Early involvement of our commissioning teams can help to eliminate the quality issues that can occur during the design, engineering and installation phases on your project.

Design flaws can lead to underperforming systems and can also affect a completed facility’s productivity and operating costs through premature equipment failure, increased energy consumption, poor indoor air quality or an uncomfortable work environment for its occupants. Proper commissioning can eliminate these concerns.

Designed to minimise the risks involved in engineering and construction, commissioning is a cost-effective way to ensure the best possible start up and handover of a facility, on-time, within budget and to specified quality standards. It also ensures that systems, equipment and occupants are ready to work at optimal productivity from day one. And that this level of performance is sustainable.

Looking at the big picture from a systems perspective, commissioning brings real-world operating insight to design and construction teams, helping them to identify issues before they escalate. What’s more, by ensuring that every aspect of a facility is designed, built and operated properly, commissioning can also help to reduce long-term operating and maintenance costs, energy consumption and liabilities.

Implemented from the design phase through to at least a year after construction, commissioning is a systematic process of ensuring that all the systems in a facility perform and interact according to the contract documents, the design intent and the owner’s operational needs.

Challenges arise at every stage of a project, from planning and design to construction, handover and operation. Commissioning is an effective way to identify problems as early as possible and resolve them quickly while there are low-cost or no-cost solutions available.

Ideally an issue will have an early birth and a short life. If undetected or unresolved until late into construction, or during testing or operation, it will be more costly to resolve.

A commissioning team that is involved in a project from the planning and design phase can highlight issues early and ensure they are resolved so that quality, cost, and schedule are not compromised.

SPGL takes a risk-based approach to commissioning and start up, focusing best practice verification and documentation procedures on the areas most likely to affect quality, cost and schedule.

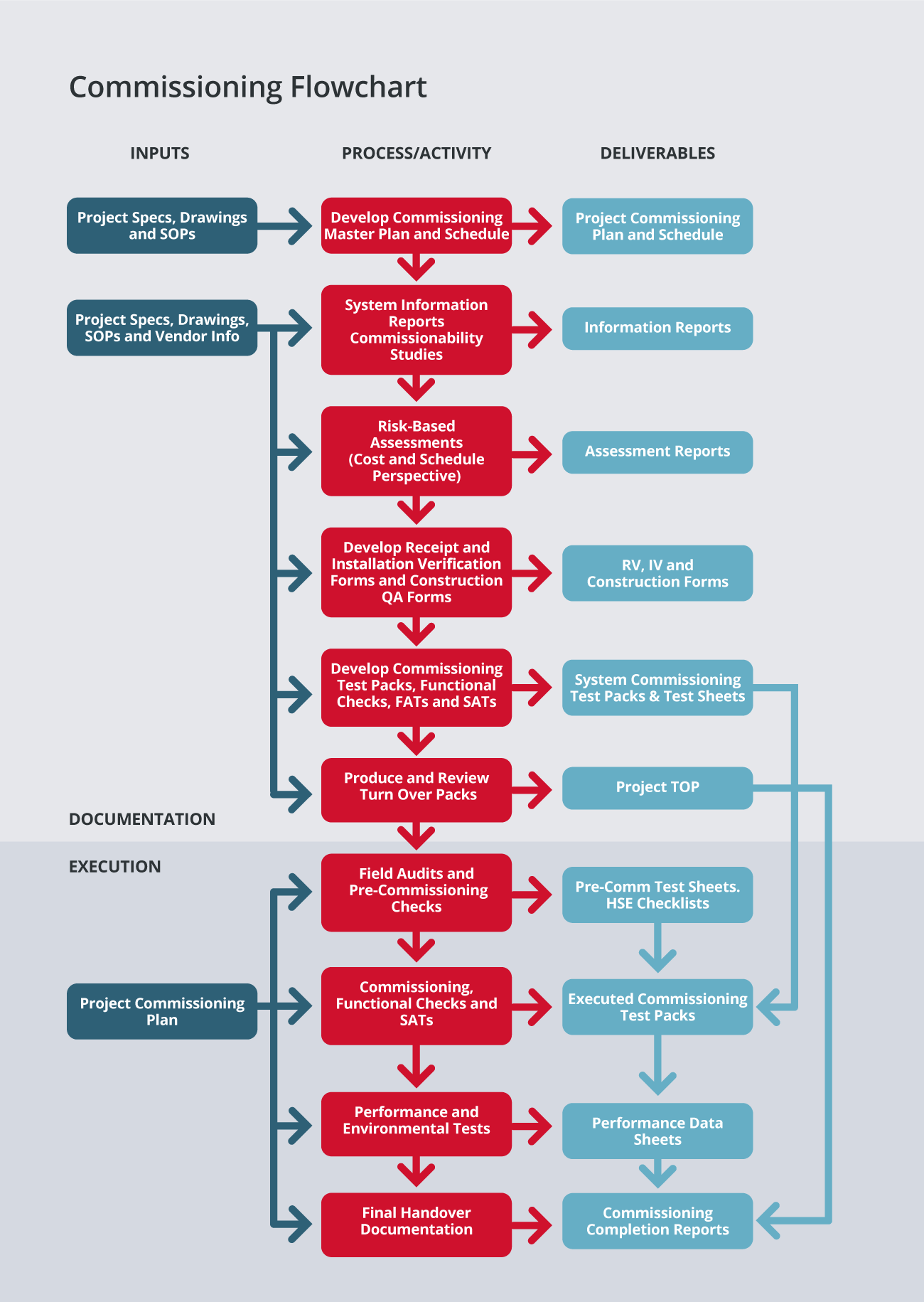

We start with a comprehensive commissioning plan which provides a route map for the project and highlights the areas that require most risk management. The plan also determines the level of documentation required for each system within a project.

Expert in commissioning facilities for the pharmaceutical industry, SPGL can produce highly detailed documentation for close scrutiny by regulatory authorities. For non-regulated industries, we simply adjust the level of detail to suit each project.

Because every project is different, SPGL offers three levels of commissioning support which can be adapted to create the ideal approach for a facility. We also provide a continuous commissioning service, extending our support post-occupancy to ensure that a facility continues to operate at optimum productivity with a healthy and comfortable work environment.

Depending on the size of the project, one or more SPGL commissioning managers would work as part of the project management team. Acting independently of the M&E contractor and commissioning teams, we would be the accepting authority for all M&E project testing, commissioning and performance testing.

An SPGL commissioning team would compile and monitor the commissioning schedule and be responsible for ensuring that all commissioning activities were executed and completed efficiently and cost effectively. For this approach to succeed, the commissioning manager must be an integral part of the project team from the design phase through to completion.

SPGL’s complete commissioning service combines the role of commissioning manager with commissioning execution, giving our team responsibility for all planning, management and execution services. The M&E contractor would be responsible for delivering systems to a defined state of mechanical completion, after which we would carry out all further activities.