Background

The US FDA has issued a discussion paper addressing the integration of artificial intelligence (AI) into the field of drug manufacturing. The goal is to review the applicability of the current FDA’s risk-based regulatory framework to AI technologies within the pharmaceutical manufacturing domain.

The discussion paper primarily concentrates on the production of New Drug Applications (NDA), Abbreviated New Drug Applications (ANDA), or Applications for Biological Marketing Authorisation (BLA).

According to the FDA, AI presents numerous opportunities for the pharmaceutical sector. Some of these include enhancing processes, ensuring intelligent maintenance, and monitoring trends for ongoing process refinement. Moreover, AI holds the potential to usher in a new era of Industry, characterised by connection and digitalisation.

Possible Impact

The FDA paper covers five key areas where AI is expected to make a substantial impact on drug manufacturing, along with some important considerations.

(1) Cloud applications

One of the advancing developments since increased digitalization, is the usage of cloud-based systems for data management, control diagnostics, process monitoring, etc. AI can be used to further analyse the cloud data to provide more insights and to further support process monitoring and Advanced Process Control, allowing dynamic control of the manufacturing process.

Esurance of data integrity and high data quality is of paramount importance in this context. And although the FDA permits the involvement of third parties’ functions in GMP manufacturing, provided it is adequately supervised, existing quality agreements between manufacturers and third parties, particularly those related to cloud data management, may have gaps in managing the risks associated with AI’s role in manufacturing monitoring and control.

During inspections, these shortcomings may give rise to challenges in ensuring that third parties establish and maintain AI software with robust safeguards for data safety and security. The FDA’s inspection approaches may need to expand to accommodate the intricacies of managing third-party cloud data and models.

(2) The increase of data

With digitalisation comes a significantly increase of process and manufacturing data, both in frequency, volume, and types of data. This data increase can influence the balance between (1) preserving data integrity and data retention and (2) managing the logistical complexities of data management. Many regulations and guidance’s already exist on data storage, but over time a more balanced approach and more clarification might be needed to ensure that an accurate record of the drug manufacturing process is still maintained. In addition, the increasing interconnection of equipment may also present challenges in preserving data stewardship, privacy, and security.

(3) AI applications and when are they subjected to regulatory oversight

The increased implementation of AI in processes like monitoring, continuous improvement, scheduling, characterisation, … leads to a need for further clarification on how AI can be integrated into production processes subject to GMP regulatory oversight.

(4) Standards for developing and validating AI models

AI can be used to control manufacturing processes and release testing in real-time. However, developing and validating a good AI model for this, is challenging as few industrial standards and guidelines are currently available for AI models that impact product quality.

New standards should be established for the development and validation of AI models in GMP processes. However, this is easier said than done as the robustness of the underlaying data shapes the AI decision making process, making it hard to avoid unintended bias during development and validation. Also, with increasing complexity it becomes harder to assess the impact of any made changes to the models.

(5) Challenges in Regulatory Oversight for AI models

The continuous learning nature of AI systems that adapt to real-time data presents a challenge for regulatory oversight. Unlike traditional models used in manufacturing, AI models can evolve over time with new information, potentially raising questions about when and to what extent notifications to regulatory authorities are required. Changes to current models are developed, validated, and updated as needed through a change control process within the pharmaceutical quality system. These do not factor in the continuous learning characteristics of AI models.

FDA’s Search for Industry Expertise

The FDA is actively seeking feedback on several key questions and discussion points from stakeholders and experts in the field:

- AI Applications: What AI applications can be envisioned for pharmaceutical manufacturing?

- Additional Aspects: Are there any additional aspects not covered in the discussion paper that the FDA should consider?

- Guidelines: Would guidelines related to artificial intelligence in pharmaceutical production be beneficial? If so, what should they encompass?

- Implementation: What elements are necessary for manufacturers to implement AI-based models in GMP manufacturing?

- Validation and Maintenance: What are the common practices for validating and maintaining self-learning AI models?

- Data Management: What mechanisms are required for managing the data used to develop AI models for pharmaceutical production?

- Unaddressed Aspects: Are there any other facets of AI application in pharmaceutical production that are not addressed in the FDA document but should be considered by the FDA?

Summary

The FDA welcomes input and insights from stakeholders and experts in the pharmaceutical industry to further develop and optimize its approach to AI integration in drug manufacturing. They recognize the transformative potential of artificial intelligence in the industry and the increased need to discuss potential impact and future challenges in regulatory control. This initiative marks a pivotal step towards harnessing AI’s potential in pharmaceutical manufacturing while maintaining regulatory rigor.

List of References

For more on this topic, please see the below reference points:-

FDA Paper on Artificial Intelligence in Drug Manufacturing – GMP Navigator (gmp-navigator.com)

Interested in learning more? Contact us today to find out how we can help with your technical needs.

Similar posts

20 February 2025

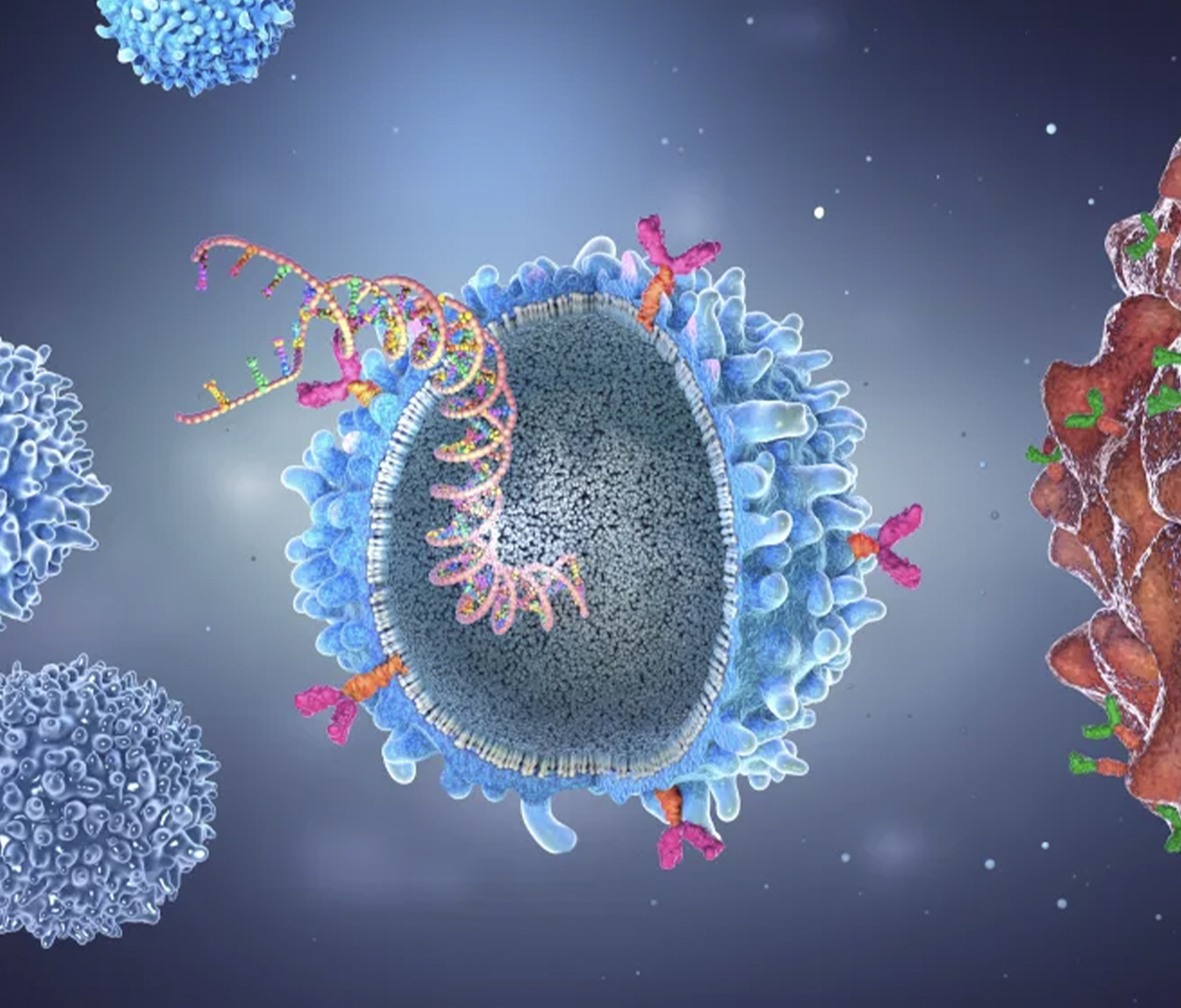

The CAR-T Revolution in Cancer Therapy